- HOME

- ABOUT US

- SERVICES

- Concrete Material Consulting

- Corrosion Assessment Services

- Drone Survey

- Inspection Services

- Nondestructive Testing

- Property Condition Assessment Services

-

Comprehensive visual inspections to assess the

general condition. - Endoscopic testing for in-depth analysis of internal structures.

- Quality Assurance for New Constructions

- Quality Assurance for New Constructions

- Compliance and Documentation

- High-Resolution Rebar Mapping

- Comprehensive Concrete Inspection

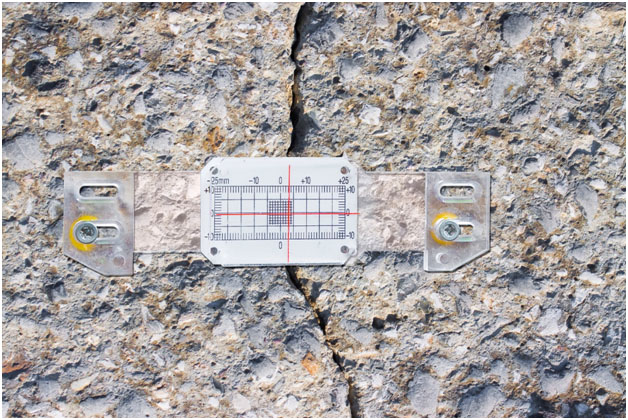

- Identification of Structural Anomalies

- Comprehensive Structural Condition Assessment

- Specialized Structural Testing

- Versatile Assessment for Diverse Structural Types

- Non-destructive Identification of the Structural defects

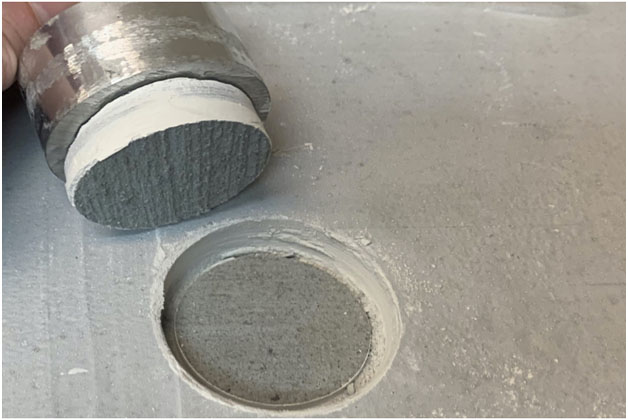

- Non-destructive in-place concrete Strength Estimation

- Concrete Repairs Evaluation

- Construction Quality Assurance

- Construction Quality Control

- Balcony Inspection per California SB

- BLOG

- CONTACT US