Introduction:

Concrete structures form the backbone of our built environment, and their integrity is paramount for safety and longevity. Assessing the health of these structures without causing any damage is a challenge met by Nondestructive Evaluation (NDE) techniques. In this article, we delve into the use of ultrasound pulse velocity, as outlined by ASTM C597, as a powerful NDE method for comprehensively evaluating the condition of concrete structures.

Understanding Nondestructive Evaluation (NDE)

Nondestructive Evaluation refers to a set of techniques employed to assess the properties of materials or structures without causing damage. In the realm of concrete structures, NDE methods play a crucial role in identifying potential issues, ensuring safety, and guiding maintenance and repair efforts.

Ultrasound Pulse Velocity and Its Role in NDE

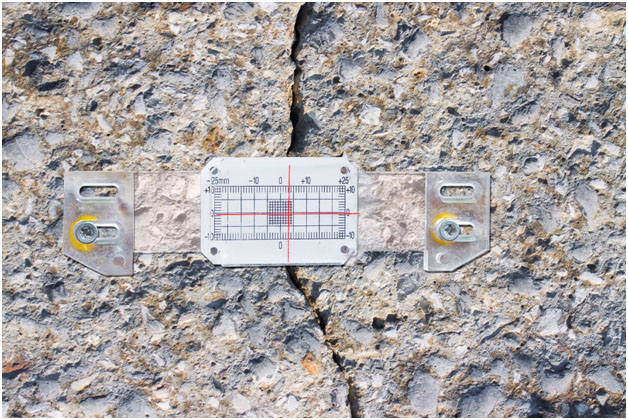

Ultrasound pulse velocity is a widely adopted NDE technique for concrete structures. It involves the transmission of ultrasonic pulses through the material, and the velocity of these pulses is measured. Variations in pulse velocity can indicate changes in the concrete’s internal structure, such as cracks, voids, or alterations in material properties.

ASTM C597 – Standard Practice for Pulse Velocity through Concrete

ASTM C597 provides a standardized approach for conducting ultrasound pulse velocity testing on concrete structures. This practice outlines the procedures for equipment calibration, test specimen preparation, and the measurement of pulse velocity. Adhering to this standard ensures consistency and reliability in results, making it a valuable tool for structural engineers and inspectors.

Conducting Ultrasound Pulse Velocity Testing

- Equipment Setup: The testing equipment, typically consisting of a transmitter and receiver, is calibrated to ensure accurate measurements. Transducers are placed on the surface of the concrete structure at specified locations.

- Pulse Transmission: Ultrasonic pulses are transmitted through the concrete, and the time taken for the pulses to travel between transducers is recorded. This time, along with the distance between transducers, is used to calculate the pulse velocity.

- Data Analysis: The obtained pulse velocity values are analyzed in comparison to established benchmarks. Variances in pulse velocity can indicate the presence of defects or anomalies within the concrete.

Section 5: Benefits of Ultrasound Pulse Velocity Testing

- Nondestructive Nature: Ultrasound pulse velocity testing allows for a comprehensive evaluation of concrete structures without causing any damage.

- Early Detection: The method enables early detection of potential issues, such as cracks or voids, allowing for proactive maintenance and repair.

- Cost-Effective: Ultrasound pulse velocity testing is a cost-effective and efficient means of assessing large areas of concrete structures in a relatively short time.

Conclusion:

In the pursuit of maintaining and enhancing the resilience of concrete structures, nondestructive evaluation techniques play a pivotal role. Ultrasound pulse velocity, as per ASTM C597, emerges as a valuable tool for engineers and inspectors. By embracing this standardized approach, we can gain deep insights into the internal condition of concrete structures, ensuring their longevity and structural integrity. As leaders in the field, Prime Test Engineering exemplifies excellence in performing NDT analyses of concrete structures, including ultrasound pulse velocity testing, contributing to the assurance of structural reliability and safety in the built environment.