Concrete: the bedrock of modern construction. Renowned for its unwavering strength and steadfast durability, it forms the very skeleton of our buildings, bridges, and roads. Yet, what happens when we need to make precise alterations to this seemingly impenetrable material? How do we navigate the complexities of embedding pipes, wires, or even windows into a substance designed to resist change?

Enter the world of concrete coring and drilling, two specialized techniques that have revolutionized the construction industry. These techniques offer controlled, precise methods for creating openings in concrete structures without compromising their integrity. Whether you’re a homeowner planning a minor renovation or a contractor overseeing a large-scale project, understanding these techniques is crucial for achieving successful and structurally sound results.

Concrete Coring vs. Drilling: A Tale of Two Techniques

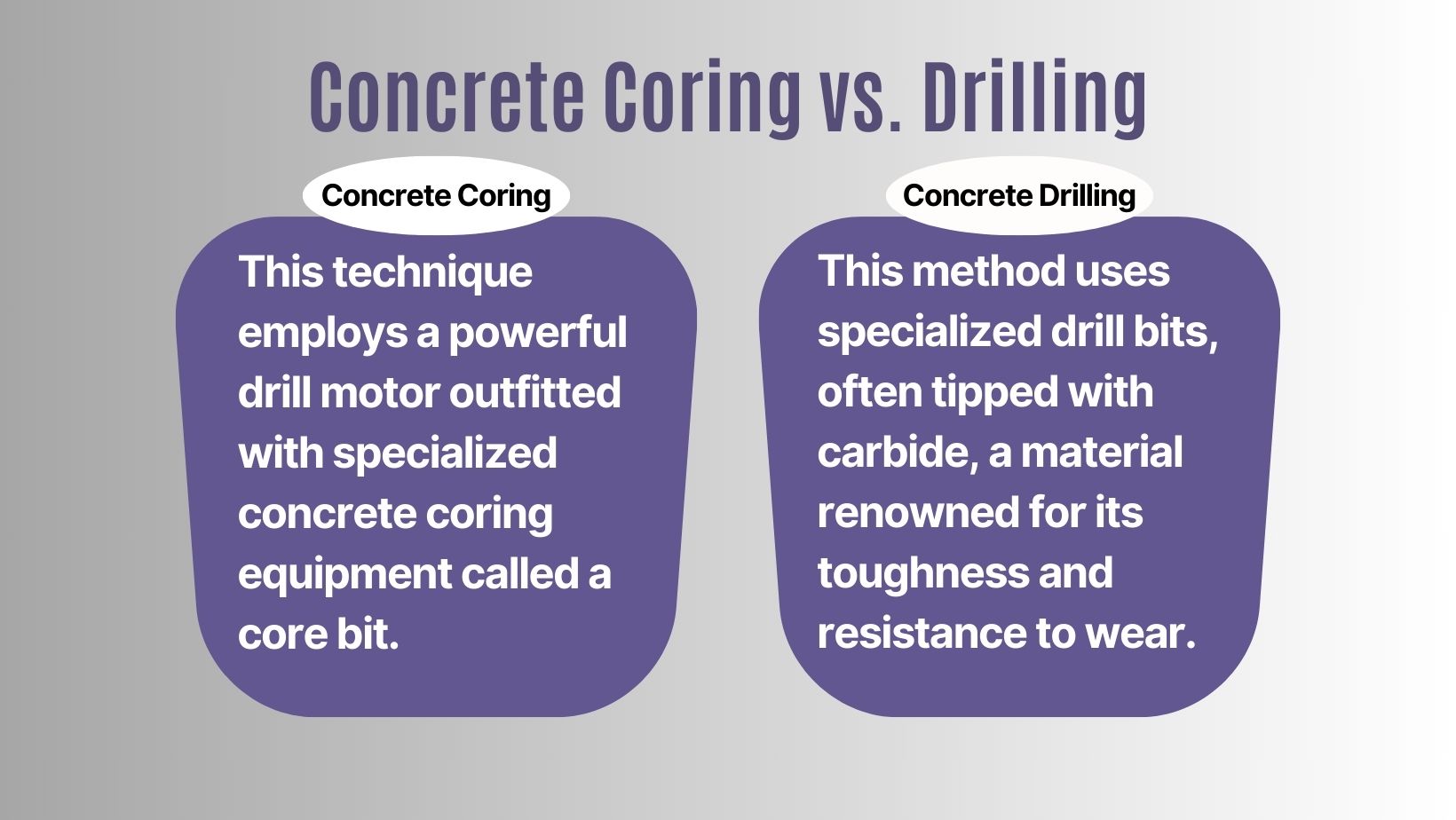

While both concrete coring and concrete drilling create perfectly cylindrical holes in concrete, their approaches differ significantly, making them suitable for specific applications:

- Concrete Coring: The Art of Extracting Cores

Imagine a giant apple core meticulously extracting the core from an apple – that’s essentially what concrete coring achieves. This technique employs a powerful drill motor outfitted with specialized concrete coring equipment called a core bit. These bits are typically studded with industrial diamonds, chosen for their exceptional hardness, which allows them to cut through even the toughest concrete with relative ease.

As the core bit rotates at high speeds, it gradually cuts a precise cylindrical core out of the concrete. This extracted core, a testament to the accuracy of the process, provides valuable insights into the concrete’s composition and strength.

- Concrete Drilling: The Power of Pulverization

Unlike coring, which extracts a solid core, concrete drilling focuses on pulverizing the concrete to create the desired opening. This method uses specialized drill bits, often tipped with carbide, a material renowned for its toughness and resistance to wear.

As the drill bit rotates at high speed, it chips away at the concrete, creating a fine powder that is easily removed. While this method doesn’t produce a core sample, it offers distinct advantages for specific applications, which we’ll explore further.

Why Choose Concrete Coring and Drilling? A Multitude of Advantages

In the realm of concrete alterations, precision reigns supreme. Traditional demolition methods, often involving jackhammers and brute force, lack the finesse and control offered by coring and drilling. Let’s delve into the compelling advantages that have made these techniques indispensable:

- Unmatched Precision for Structural Integrity: Creating precise openings is paramount for maintaining the structural integrity of concrete structures. Both coring and drilling minimize vibrations that can lead to unintended cracking or weakening of the surrounding concrete.

- Versatility for Projects Big and Small: The adaptability of these techniques shines through in their ability to handle a vast range of applications. Whether it’s creating small, precise openings for electrical conduits in a residential building or large-scale excavations for ventilation systems in a skyscraper, coring and drilling rise to the occasion.

- Minimizing Disruption, Maximizing Productivity: In our fast-paced world, time is of the essence, and minimizing disruptions during construction is crucial. Concrete coring and cutting techniques generate significantly less noise and dust compared to traditional methods, making them ideal for occupied buildings or environments sensitive to disruptions.

- Prioritizing Safety, Reducing Risks: Construction sites inherently present safety hazards, and uncontrolled concrete removal can exacerbate these risks. By providing controlled and predictable concrete removal, coring and drilling contributes to a safer working environment for everyone involved.

Concrete Coring and Drilling in Action: A World of Applications

These techniques, once considered specialized, have become indispensable across a wide range of construction and engineering projects. Let’s explore some real-world applications where they truly shine:

- Plumbing and Electrical Installations Made Seamless: Creating pathways for essential services like plumbing and electrical systems demands precision. Coring and drilling excel in this domain, allowing for the accurate placement of pipes, conduits, and wiring within concrete structures.

- HVAC System Integration Without a Hitch: Modern buildings rely heavily on HVAC systems for climate control, and integrating these systems often requires creating openings for ductwork, vents, and other components. Coring and drilling provide the accuracy and efficiency needed for seamless HVAC installations.

- Structural Modifications, Reinforcements, and More: Whether it’s adding windows to an existing concrete wall, creating openings for doors, or reinforcing existing structures with steel rods, these techniques offer the controlled precision needed for successful structural modifications.

- Soil Testing and Sampling: Unlocking Insights from Within: Understanding the composition and load-bearing capacity of the soil beneath a structure is crucial for ensuring its long-term stability. Concrete coring provides a means to extract core samples for analysis, giving engineers valuable insights into the ground conditions.

- Infrastructure Projects: Building the Backbone of Modern Society: From massive bridges spanning rivers to intricate networks of underground tunnels, infrastructure projects rely heavily on concrete. Coring and drilling play vital roles in these endeavors, enabling the installation of post-tensioning cables, the creation of drainage systems, and much more.

Choosing the Right Technique: Factors to Consider

While both coring and drilling create holes in concrete, understanding their strengths and limitations will help you choose the most suitable technique for your specific project:

When to Choose Concrete Coring:

- Large Diameter Holes: When the project requires holes larger than 2 inches in diameter, coring often proves to be the more efficient and precise method.

- Deep, Precise Openings: Coring excels at creating deep holes with tight tolerances, making it ideal for applications where accuracy is paramount.

- Core Sample Analysis: If analyzing the extracted concrete core for composition, strength, or other properties is essential, coring becomes the only viable option.

- Heavily Reinforced Concrete: Coring effectively cuts through heavily reinforced concrete, making it suitable for projects involving thick walls or high-strength concrete.

When to Choose Concrete Drilling:

- Smaller Diameter Holes: Drilling often proves faster and more cost-effective for creating smaller diameter holes, typically less than 2 inches in diameter.

- Shallow Depths: For applications requiring shallower holes, drilling offers a quicker and more agile solution.

- Budget-Conscious Projects: Drilling often comes with lower costs compared to coring, especially for smaller jobs, making it an attractive option when budget constraints are a factor.

Finding Concrete Coring Near Me: Partnering with Expertise

Concrete coring and drilling are specialized techniques best left to experienced professionals equipped with the right tools and expertise. Attempting these methods without proper training and safety measures can lead to costly mistakes, structural damage, and even personal injury.

When searching for a reputable concrete coring company near me, consider these essential factors:

- Experience and Expertise for Optimal Results: Look for a company with a proven track record of completed projects similar to yours. A team with extensive experience will have encountered a wider range of challenges and developed effective solutions.

- Prioritizing Safety for Peace of Mind: Safety should be a top priority for any contractor you consider. Look for companies with a strong commitment to safety protocols, evident in their certifications, training programs, and use of appropriate safety equipment.

- Cutting-Edge Equipment for Efficiency and Precision: The quality of the equipment used directly impacts the speed, accuracy, and overall success of the project. A reputable concrete coring company will invest in modern, well-maintained concrete coring equipment to ensure optimal results.

- Positive Reputation: A Testament to Quality and Reliability: Online reviews and testimonials provide valuable insights into the experiences of past clients. Take the time to research the company’s reputation, looking for positive feedback and testimonials that highlight their professionalism, reliability, and quality of work.

- Comprehensive Concrete Coring and Cutting Services: Choosing a company that offers a comprehensive range of services, including both cutting and concrete coring services, can simplify your project management.

- Service Area: Ensuring Local Expertise: Confirm that the company you choose operates in your specific geographical area. Local expertise ensures they are familiar with local building codes and regulations, streamlining the project’s execution.

Conclusion: Embracing Precision, Ensuring Success

Concrete, once poured and set, might seem like an immovable object. However, concrete coring and drilling have emerged as the twin pillars of controlled concrete alteration, offering a combination of precision, efficiency, and safety unmatched by traditional methods.

By understanding these techniques, their applications, and the importance of partnering with experienced professionals, you empower yourself to make informed decisions that contribute to the success of your project, regardless of its scale or complexity.

FAQs:

When is concrete coring the best option for my project?

Coring is ideal for large diameter holes (typically 2 inches or more), deep and precise openings, projects requiring core sample analysis, and when working with heavily reinforced concrete.

How do I find a reputable concrete coring company near me?

Start by searching online for "concrete coring near me" or "concrete coring company near me." Look for companies with extensive experience, a strong commitment to safety, modern equipment, positive online reviews and testimonials, and a comprehensive range of services.

Is it safe to attempt concrete coring or drilling myself?

No, concrete coring and drilling require specialized skills, knowledge, and equipment. Attempting these techniques without proper training and safety precautions can lead to serious injuries and structural damage. Always hire experienced professionals for these tasks.

What information should I provide to a concrete coring contractor for a quote?

To receive an accurate quote, be prepared to provide details such as the location of the project, the diameter and depth of the required holes, the type and thickness of the concrete, any potential obstructions (rebar, pipes, etc.), and the desired timeframe for completion.